This is the second in a series of posts each covering an aspect of brewing mixed-fermentation barrel-aged beers where my opinions have changed significantly since I wrote American Sour Beers 10 years ago. Each post will focus on our process, recipe, and results for one of the beers in the Sapwood Cellars Shipping Club (includes 6 bottles, for $146, cancel anytime) - sign-ups for the first box close May 5th! This post covers blending through the lens of Growth Rings 2023 (our blend of 1-, 2-, and 3-year barrel-aged sours). If you are closer to the brewery, May 10th and 11th I'll be doing a talk and vintage sour tasting including pours of Growth Rings 2021 and 2023!

As a homebrewer, my experience with blending was limited to a handful of batches. Over the last six years I've had a hand in blending more than 70 batches of barrel-aged sour beer. So, I thought it would be valuable to give my thoughts on the process, what I've learned to do, and not to do.

Setting Yourself Up For Success

You can't blend great beer if you don't have options. Creating variety starts on brew day and continues through fermentation and aging.

Malt Bills - More so for darker sours, it's good to have options for beers that have different flavors to pull from. Even for pale beers, having different grains (wheat, oats, rye, spelt, light caramel malt etc.), and starting gravities can be valuable for creating range.

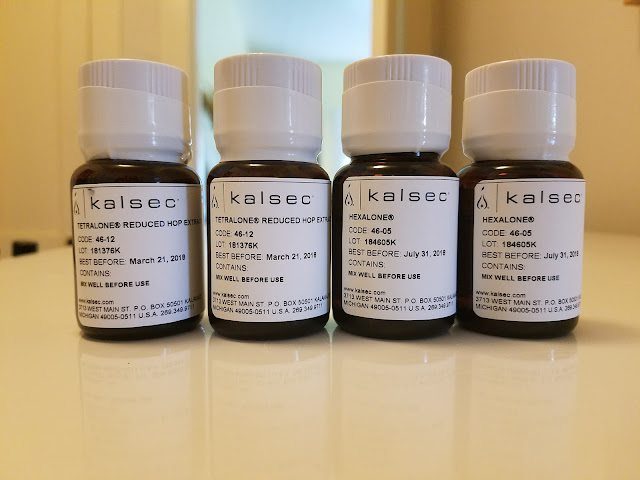

Hopping Rates - As I discussed in my previous post, hopping rate plays a large role in acidity and "funky" aromatics. Bitterness itself can be a valuable flavor in a blend, it's a flavor present in most lambics, and too often missing from American sours.

Acidity - Having "Brett only" barrels is a good way to ensure you have beer available that won't be too acidic. When a barrel starts getting too sour, we'll often keg it so it is available for blending at a low level for beers that aren't sour enough.

Barrels - A blend of "new" and well-used barrels. Early on all of our barrels were first-use (to us). As a result many of our early releases were too woody, giving "lumber aisle" vibes. Most sour beers are light and delicate and too much oak can overwhelm. At the same time, it's good to retire barrels that aren't producing spectacular beer allowing you to bring in new characterful barrels (we currently have fresh gin, Madeira, PX Sherry etc. aging). If I was starting a new barrel program, I'd soak half of the barrels slated for pale beers with multiple changes of hot water to leach out oak flavor and tannins before filling.

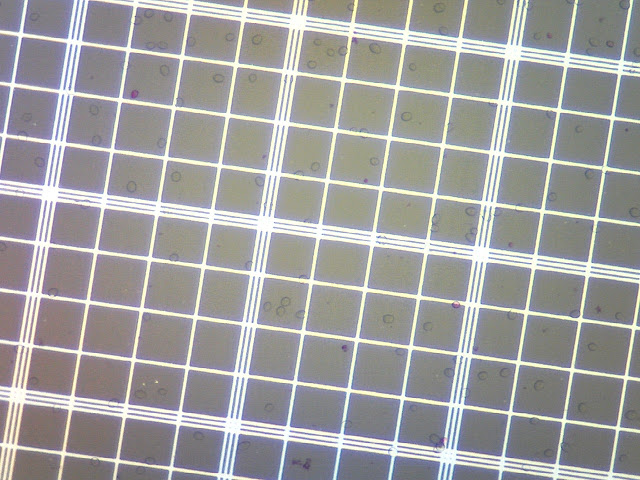

Microbes - It is easiest if you have the same culture in all of the beers/barrels. In that case you don't have to worry about additional attenuation after packaging. For me, it's more valuable to have a variety of microbes for different acid levels and Brett profiles for more dynamic flavor options. As time has gone on we've split the difference, pumping in some of a favorite barrel to a fresh batch, but then going into various barrels with their own cultures. We'll also pitch additional microbes if a barrel isn't headed in a good direction at 6-12 months.

Ages - It can be helpful to have the same/similar beers of various ages so you can balance flavors. We've gotten better at judging which barrels just need more time, and which are headed in a bad direction and need to be dumped. That said, I don't have as much time to taste/monitor the barrels as I should and I still "miss" some good barrels leaving them in too long until they taste oxidized or off.

The Mechanics of Blending

Think about the goals before you start. What is the concept? What other ingredients are you adding after blending? What is the target volume? Sometimes it is good to just taste barrels for inspiration, but that can be overwhelming when you have dozens of barrels to select from. I try to set a general schedule before the year starts. It keeps me on track for seasonal ingredients, sourcing barrels for finishing, and utilizing our staff/tank time rather than bunching up releases. I tend to earmark barrels as "potential" candidates for a blend, ideally twice as many barrels as a blend would require.

From there, I go to our barrel-spreadsheet (more info). I filter for beers with enough age, appropriate bases, removing barrels that are already earmarked for other projects. Lots of releases overlap, say I fill five barrels with sour red and hope to get a two-barrel blend plain and a two-barrel blend with fruit. Hopefully I have an "orphan" barrel that was passed over from last year or another similar base that didn't fit in its blend available for variety. Then I start pulling nails and tasting to gauge my options. I note barrels that need more time and those that are running out of time. Hopefully that narrows down my choices to five barrels at most for a two or three barrel blend.

Then I pull larger samples of those barrels so I have enough beer for a few blends without having to go back and pull more. When possible, I try to create full-barrel blends, although we occasionally keg-off partial barrels for future blending stock. In the same way if a blend is missing a little something, I'll take a look through our kegs and see if there is an option that satisfies the need.

I usually break down my options by acidity. If two barrels are a bit too acidic and two are not acidic enough, I'll try blending my favorite from each camp together to see where that gets me. Then swap in the other if there is something that doesn't work. Once I get a solid blend, I might go hunting for a little something extra. For example we were just blending a sour red, and ended up with a little 3+ year-aged Vin de Cereale (strong sour red) as a low-percentage malt-booster bringing perceived sweetness and more oak.

In terms of the practicalities of blending, I usually use volume. Weight works, but I tend not to worry about extreme precision because the volume in each barrel can differ by 5-10% anyway. For each blend I start with an empty cup to avoid issues with tracking when you take a sip, dose in more and then don't really know the ratio.

Finally, I write down the winning blend. When possible, I come back and taste the blend on a fresh palate later, ideally with someone who wasn't involved in the initial blend (since that is how the majority of people drinking the beer will approach it).

Blending takes time and practice, but one thing that has been immensely helpful is blending with other people. Some of my favorite collabs are sensory rather than recipe-based. There isn't often much I get out of brewing a collab beer, instead we invite in other brewers to taste through our barrels and help select a blend, brainstorm adjuncts etc. Sam, Tim, and co. from Other Half helped blend Throwing Hearts. Jennings from Pen Druid came in to blend Life is Ridiculous. Mike Thorpe from Afterthought visited last week to blend an upcoming beer with hardy kiwi and New Zealand hops. We've done similar things on the stout side with Mike Saboe from Toppling Goliath and Eric Padilla from More/Open Outcry. Heck it's just great bringing in homebrew friends with good palates to help taste barrels, bounce ideas off... and just give me an excuse to pull samples!

Recipe: Growth Rings 2023

Barrel #16

Beer: Golden Sour (Pils, 2-row, Chit, Wheat Malt, .5 lbs/bbl Aged Hops, 1.056)

Age: 16 Months

Barrel: 5th-fill Pinot Noir American Oak

Culture East Coast Yeast Flemish Ale

Notes: Rubbery funk, medium acid, bright, good

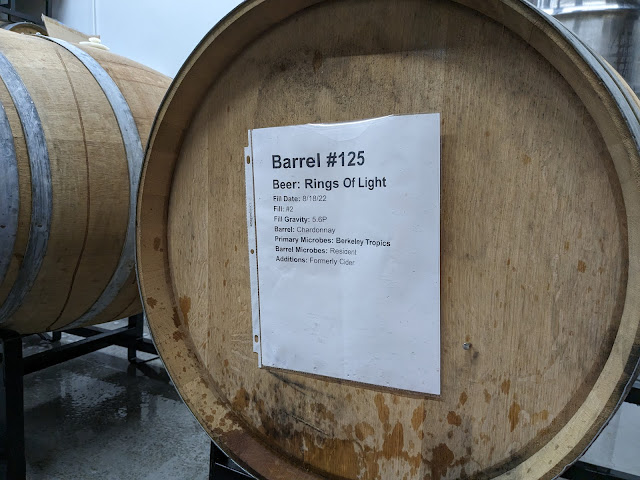

Barrel #19

Beer: Rings of Light (2-row, Chit, Malted Wheat, Unmalted Oats, 40 IBUs in Whirlpool, 1.062)

Age: 8 months

Barrel: 4th-fill Chardonnay American Oak.

Culture: Omega Brett C and Yeast Bay Amalgamation

Notes: Less acidic, funky, bright fruit, rubbery

Barrel #20

Beer: Marylandbic (Pils, Unmalted Wheat, Chit, .5 lbs/bbl 2014 Celeia pellets, 1.045)

Age: 35 months.

Barrel: 2nd-fill Chardonnay American Oak.

Culture: Omega Brett C and Yeast Bay Amalgamation (plus a house culture that was a repitch of a repitch in primary)

Notes: Loamy, a touch stale, bright lactic acid.

Barrel #62

Beer: Belgian Pale (Pilsner, Wheat Malt, Vienna, 15 IBUs Sterling First Wort, 1.048)

Age: 27 months

Barrel: 2nd-fill Cabernet Franc French Oak

Culture: SARA Saison Bernice

Notes: Sprite, tart, but not highly acidic.

Growth Rings is the rare bottle-conditioned sour that we didn't repitch with wine yeast, a good choice if you're looking to harvest bottle dregs!

Tasting Notes: Growth Rings 2023

(My personal notes from a few months ago)

Smell - Citrusy nose, apricot, hay, bright and fresh. Missing that big rubber that is present in most great lambics.

Appearance - Pale gold, clear, lots of bubbles, thick head, good retention. Great lacing.

Taste - Delicate acidity. Lemon, apricot, just a touch of rubber.

Mouthfeel - Snappy carbonation, medium-light body. Lighter bodied than a classic Gueuze.

Drinkability - In terms of drinkability, it’s my favorite recently. Lively, complex… but it isn't as gueuze-y.

Changes for Next Time - It has sort of a barrel-aged saison quality more than gueuze. Maybe that fresher whirlpool hop character from Rings of Light… that said I really like the result.